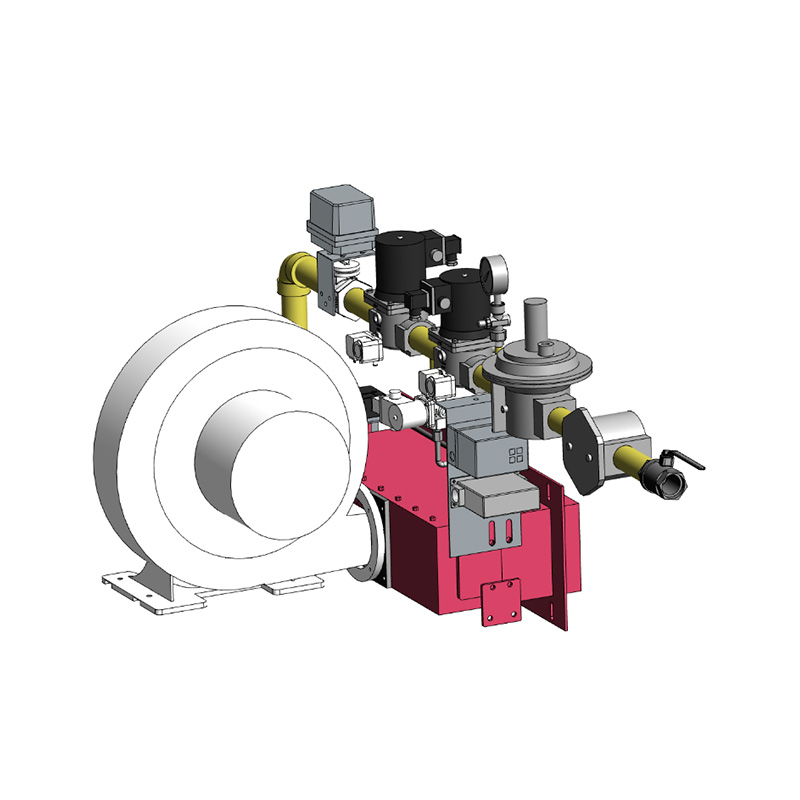

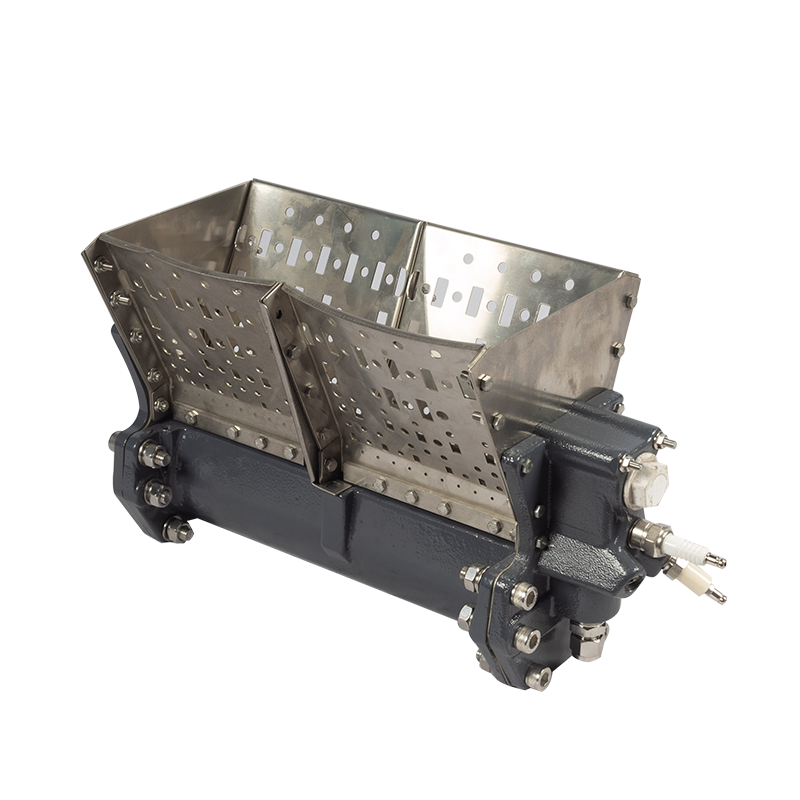

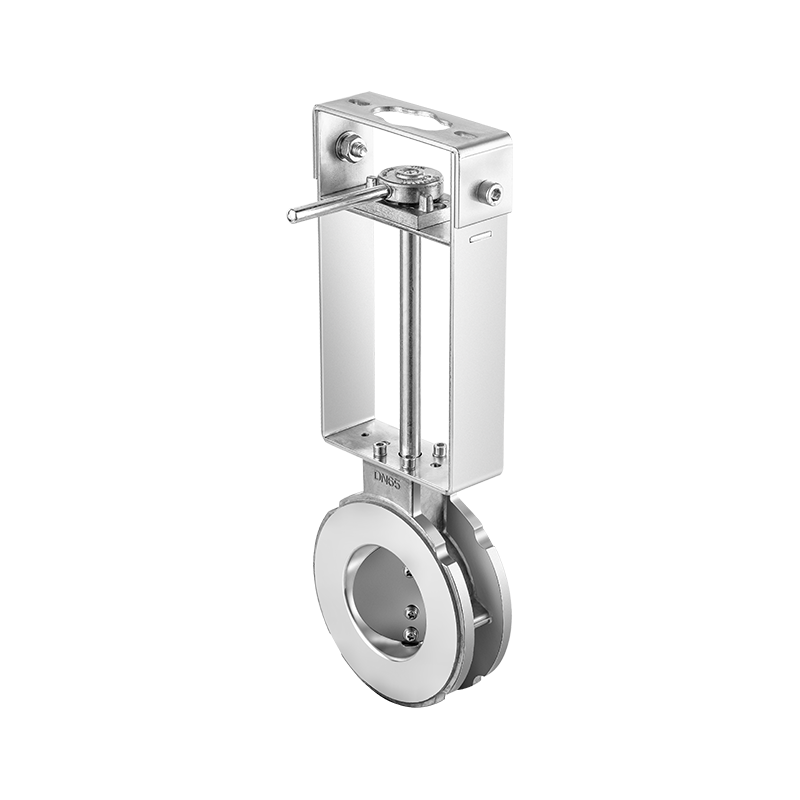

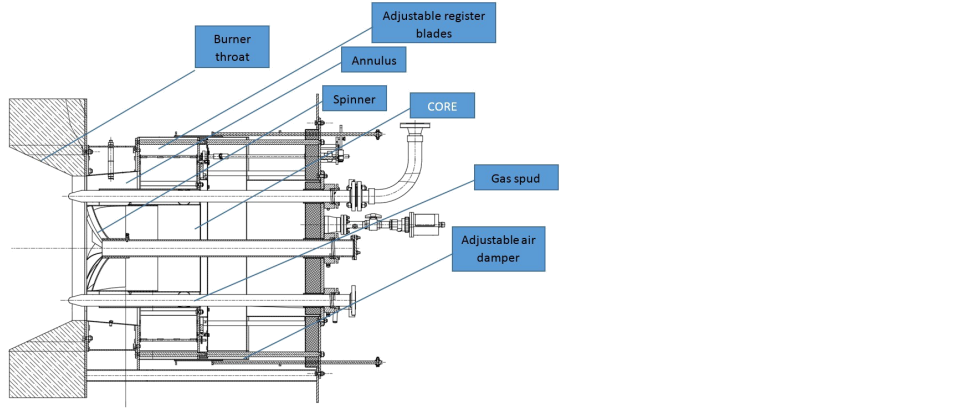

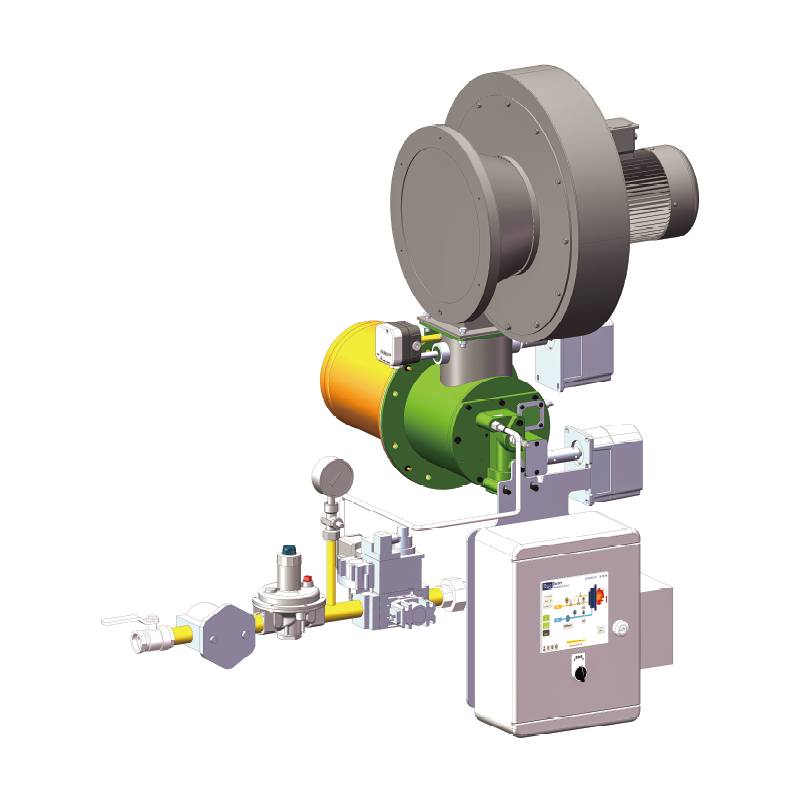

Burner structure

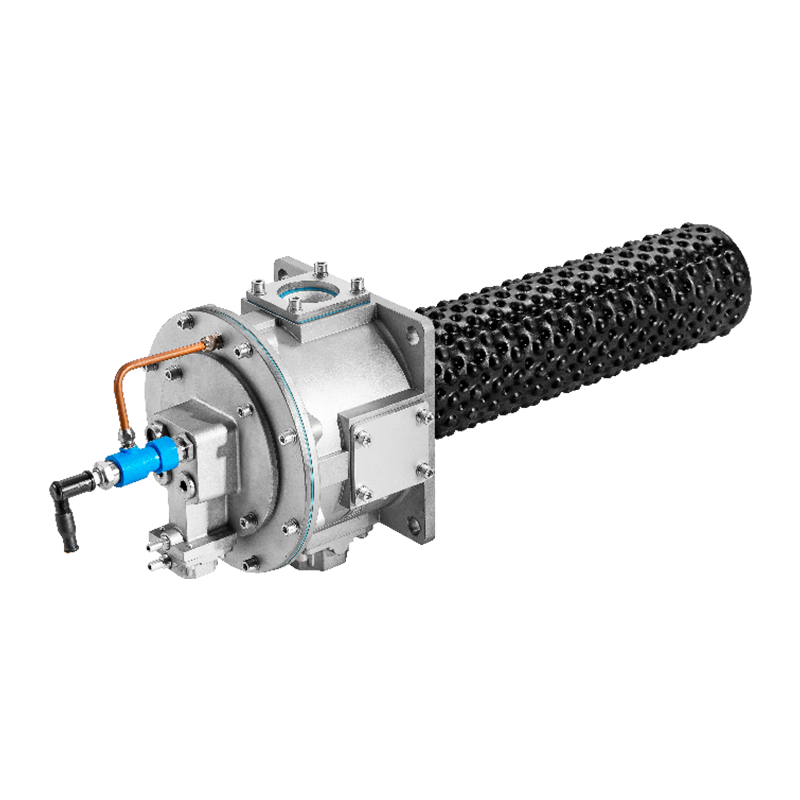

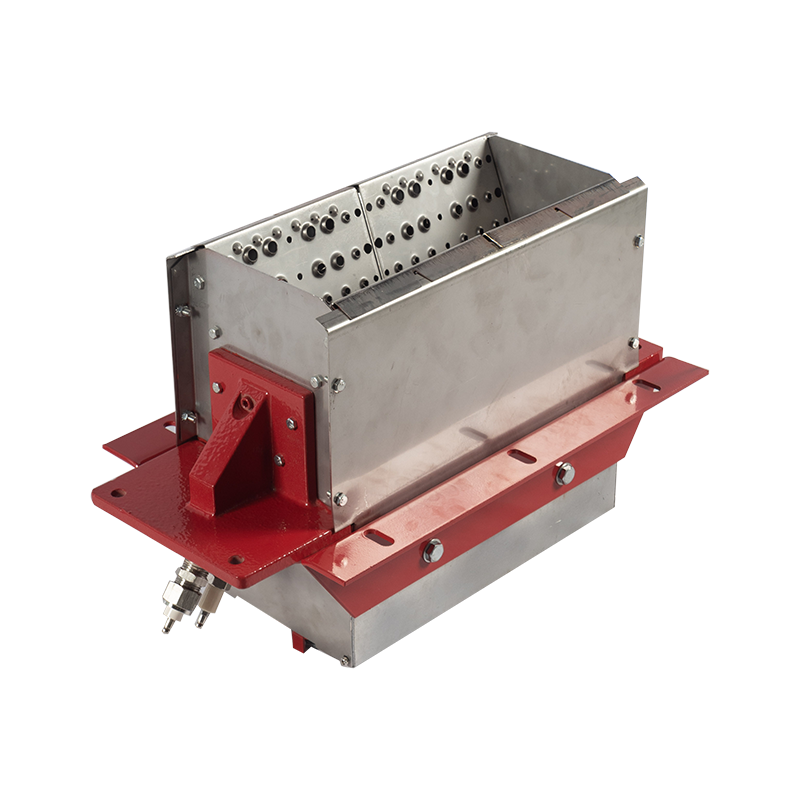

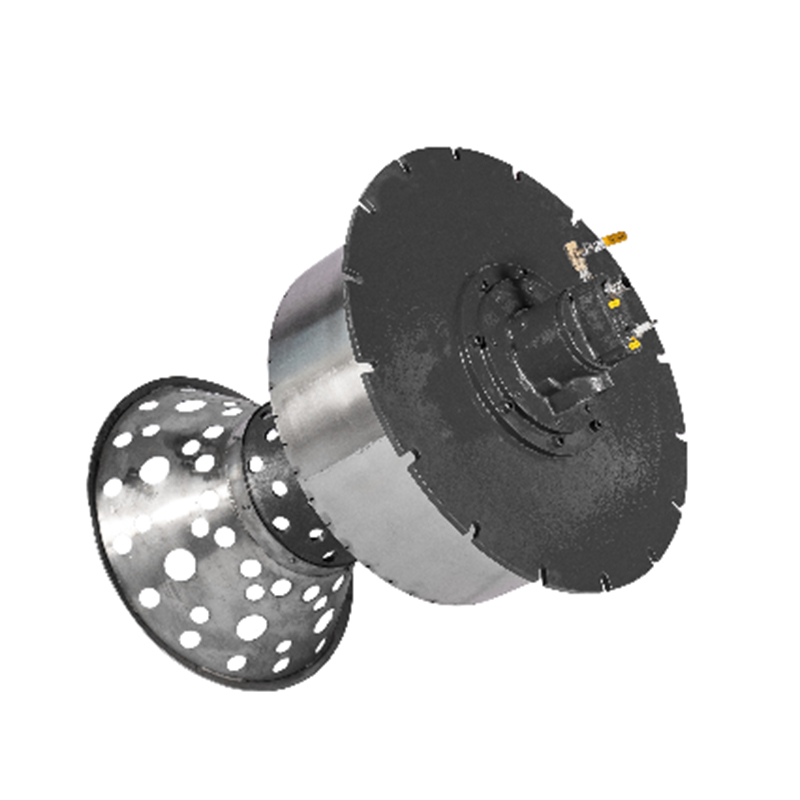

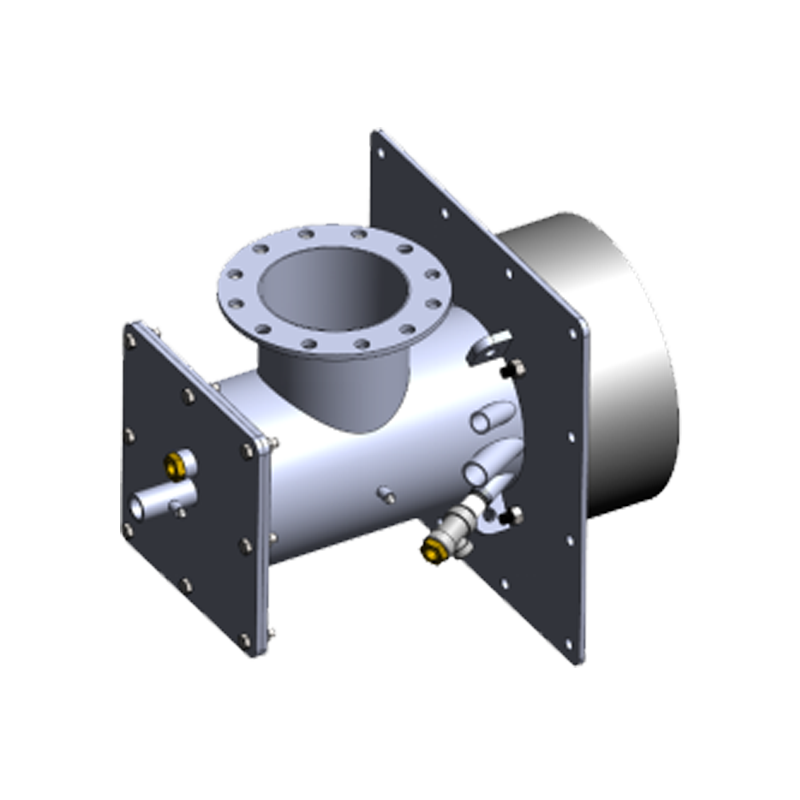

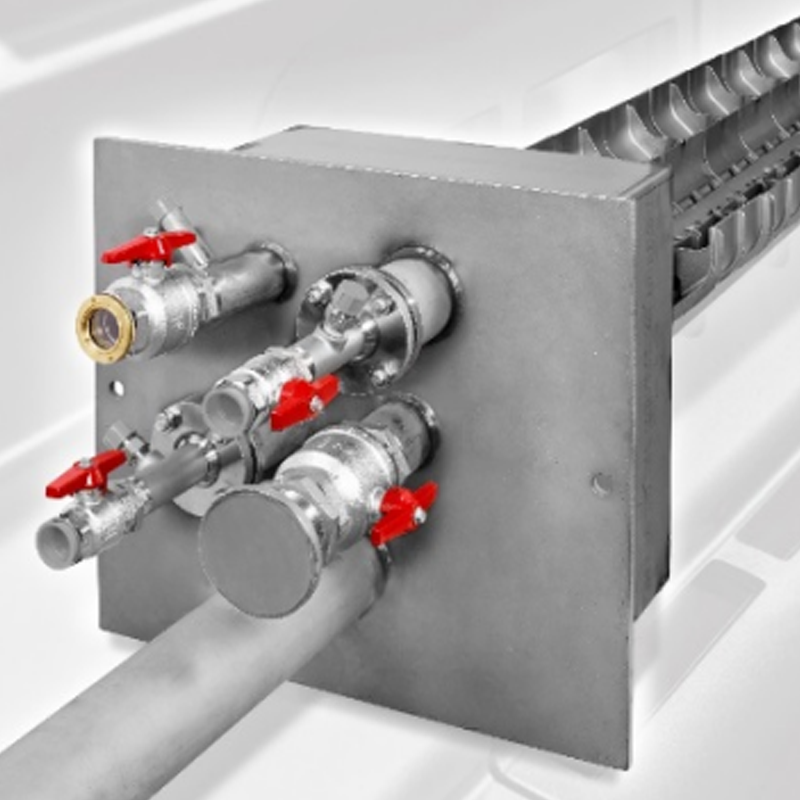

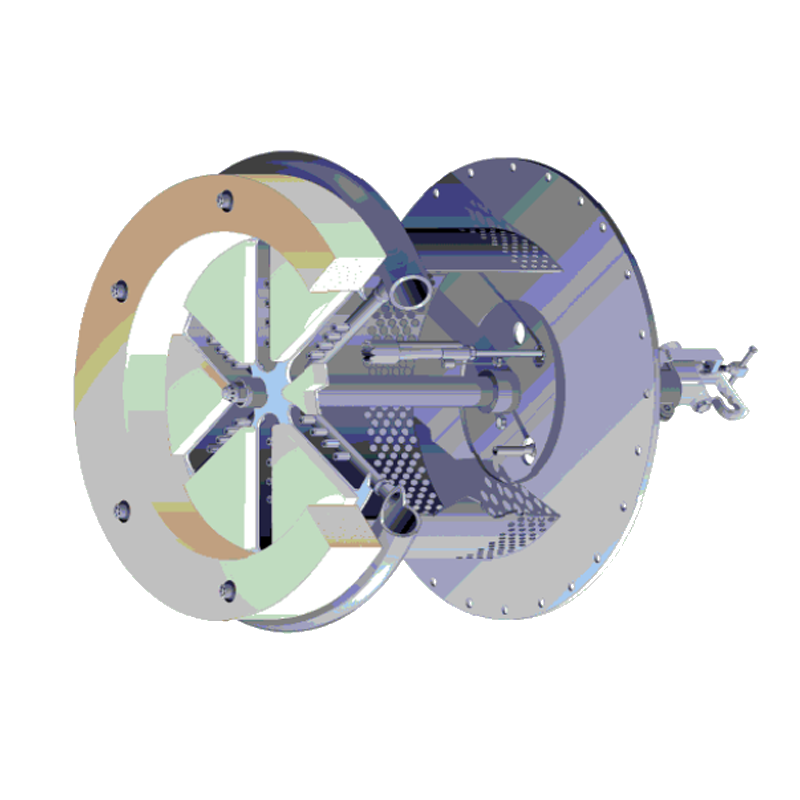

Combustion air enters the burner through the wind box and is then divided into primary air and secondary air. Adjusting the air damper can change the ratio of primary air to secondary air. The flap drive is adjusted by two control rods at the front of the burner. The primary air of the burner is rotated by a spinner located at the center of the burner, and the secondary air is rotated by adjusting the register blades at the front of the burner.

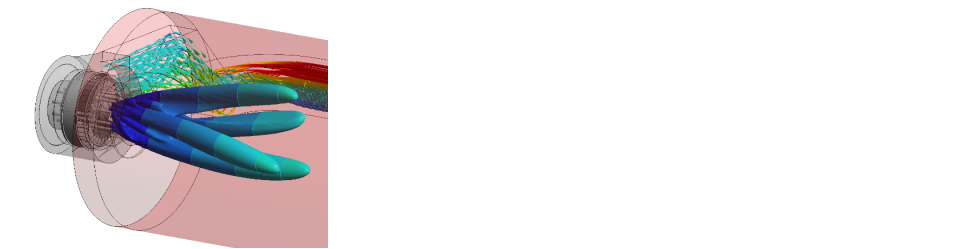

The burner applied air staging, fuel staging, and internal flue gas recirculation to minimize NOx emissions. The multi-nozzle design enables fuel staging, which helps reduce NOx formation by lowering local flame temperatures.

The primary air forms a strong central recirculation zone directly downstream of the swirler, contributing to burner stability across the entire combustion range. The external annulus air zone uses adjustable vortices for flame shaping, optimizing flame characteristics and emission levels.

The swirler generates a robust recirculation zone that aids in NOx reduction. This zone, as a source of flue gas, causes the fuel jet to entrain gases locally. Along with the proprietary gas nozzle design, this mechanism helps reduce thermal NOx formation.

Specifications

Burner ranting from 2-145Mw

NOx<15ppm @ 3% O2

Nature gas, fuel gas and special gas mixer

Adjustable flame share & emission

Burner CFD simulation

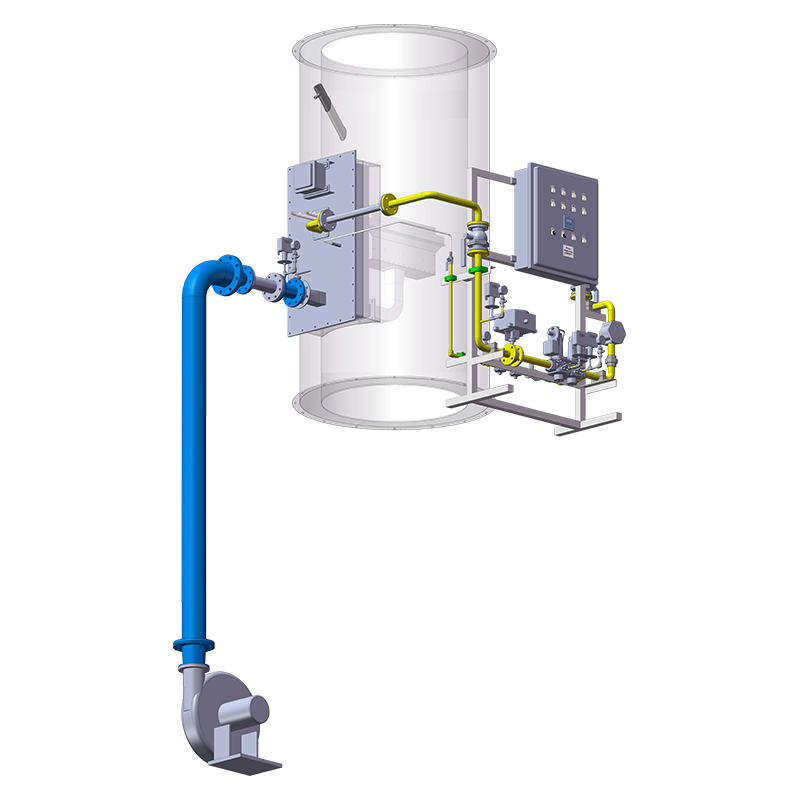

CBLN burner installations

BASF China CBLN burner with nature gas and Oligomer (waste liquid)

English

English 中文简体

中文简体 русский

русский

.jpg)