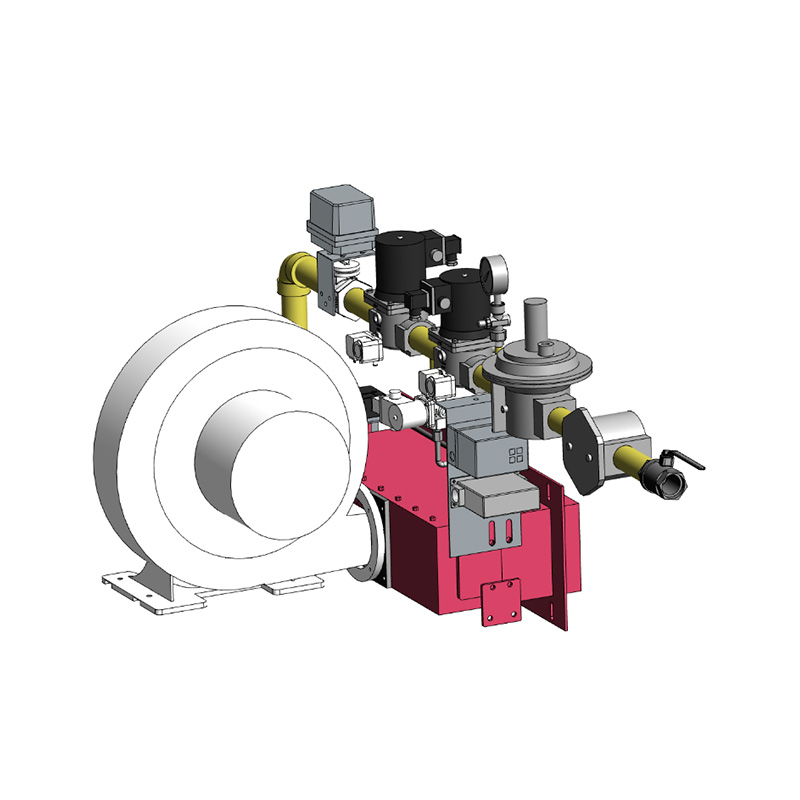

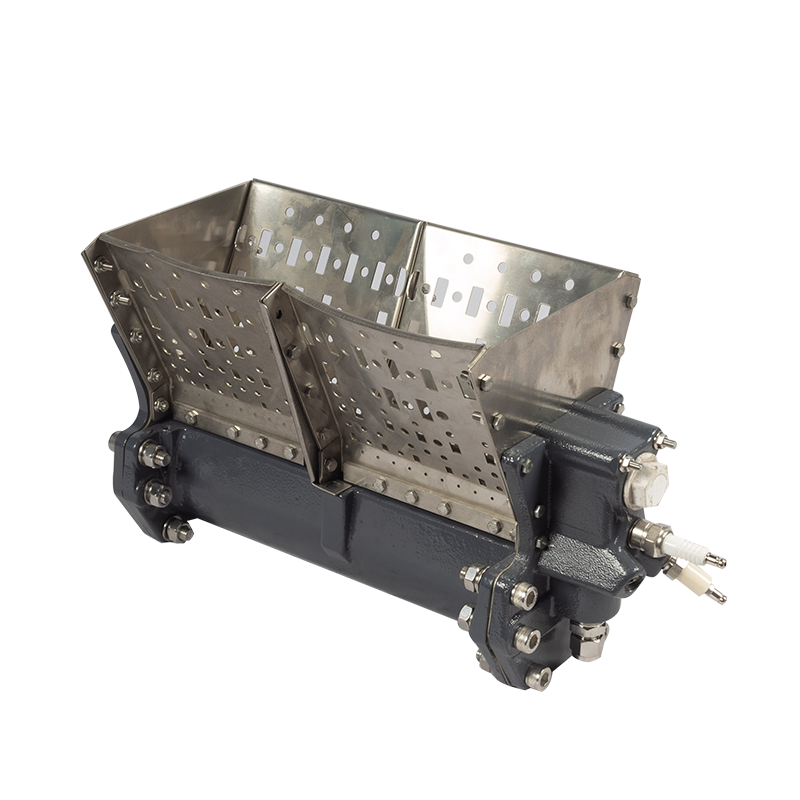

Grid duct burner type

Features and benefits

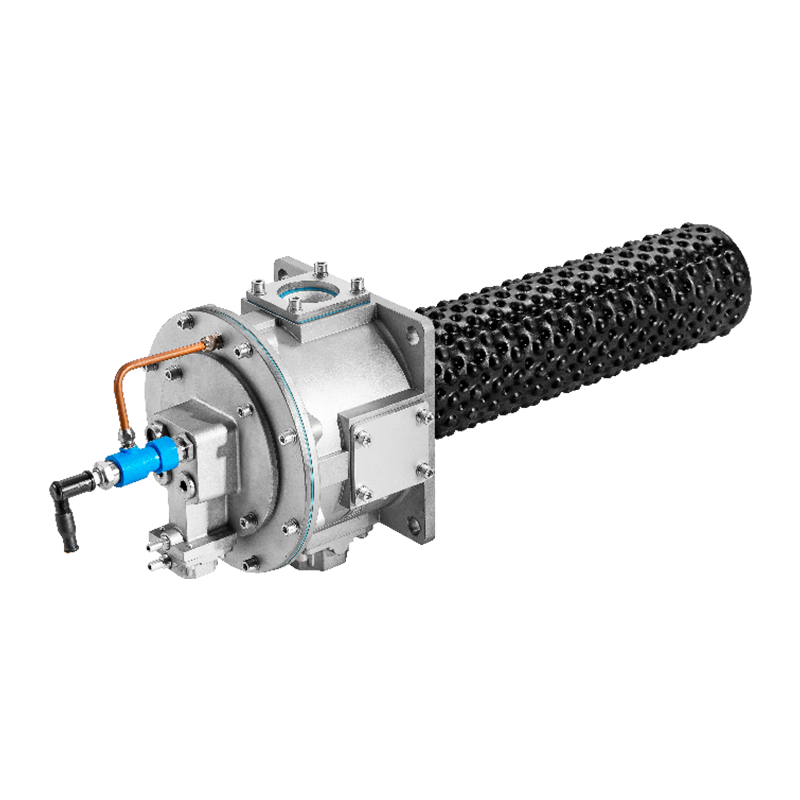

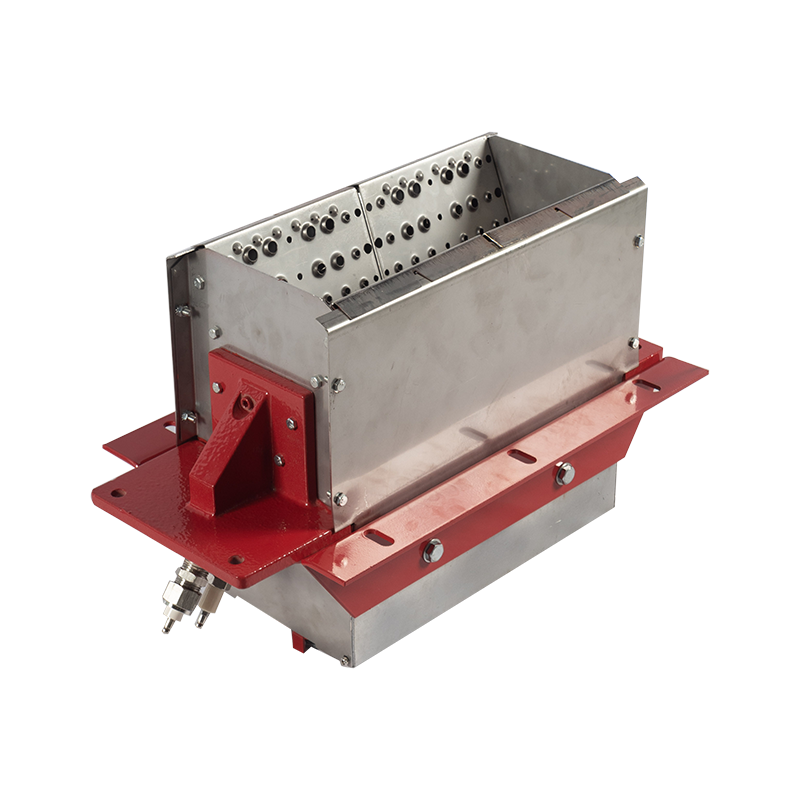

√ Modular design

The grid type burner is of modular design which can be adapted to each specific application.

√ Low maintenance cost

The grid type burner design, which is made up of heavy casted stainless steel flame stabilizers and high-grade stainless-steel construction, is very robust and assures a long lifetime of the burner without requiring any maintenance.

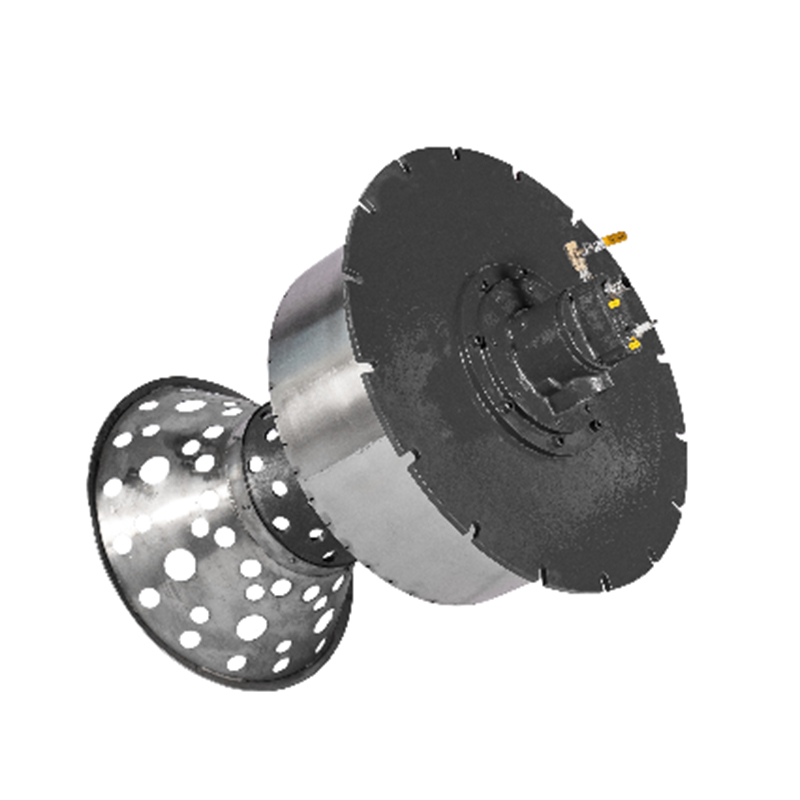

√ Low emissions, high stability

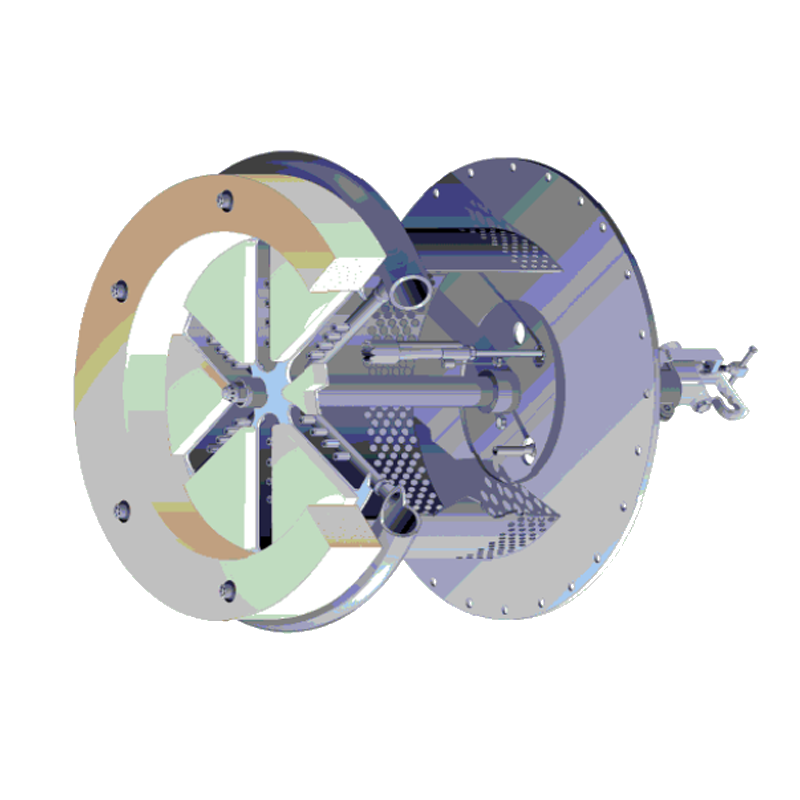

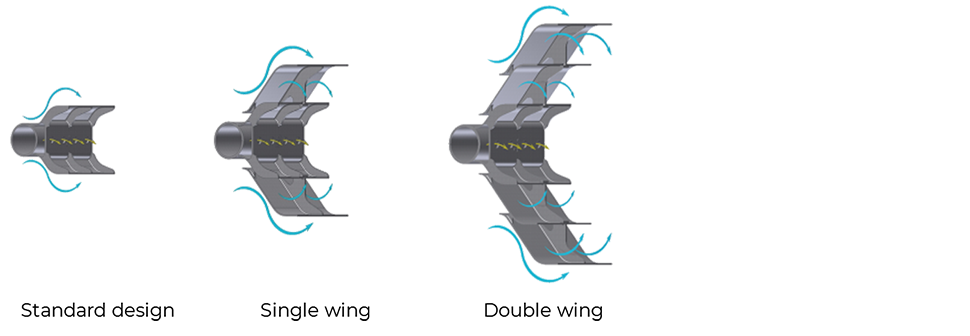

The special shape of the burner wings assures stable combustion over the total operating range resulting in low emissions of NOx, CO and UHC’s.

√ Fuel flexibility

Grid type duct burners operate on a broad range of fuels ranging from fuels containing hydrogen to fuels containing heavies or olefins.

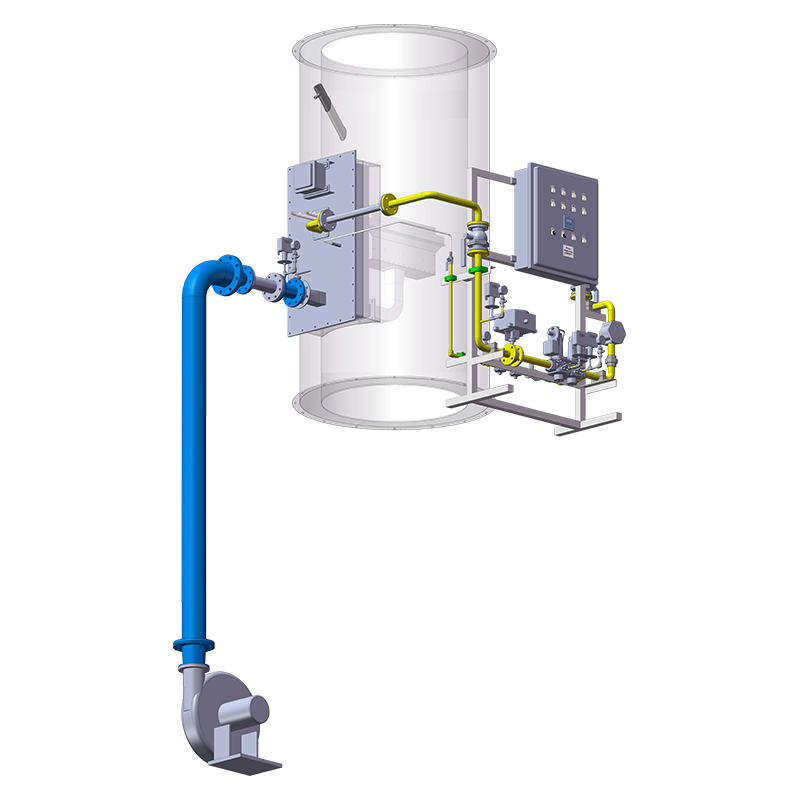

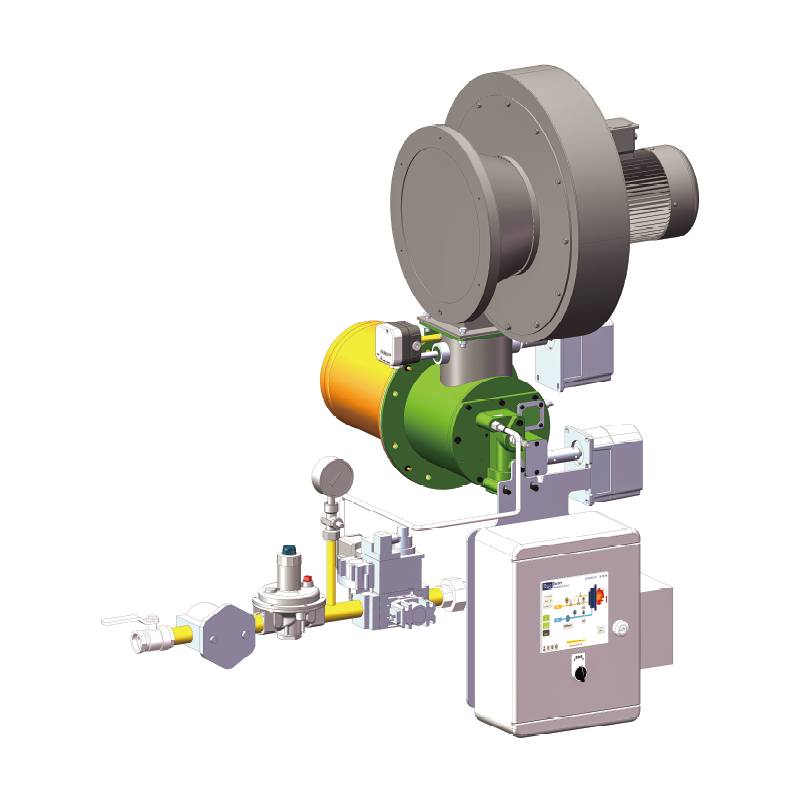

√ Fresh air firing

Grid type duct burners can be used as a backup system to continue HRSG operation when the turbine is stopped. In that case, fresh air from combustion air fans is routed to the duct.

Technical specifications

√ Firing temperature up to 1100˚ C

√ Typical heat input 2.35Mw-4Mw/m

√ Short flame design (approx. 3.5m)

√ Low pressure drops (approx. 1-2mbar)

√ Good temperature distribution

√ Turndown ratio: 10:1

√ Suitable for kinds of fuel gas, NG, LPG, H2, Syngas, biogas

√ Works for O2 from 10%-16% in turbine exhaust gas

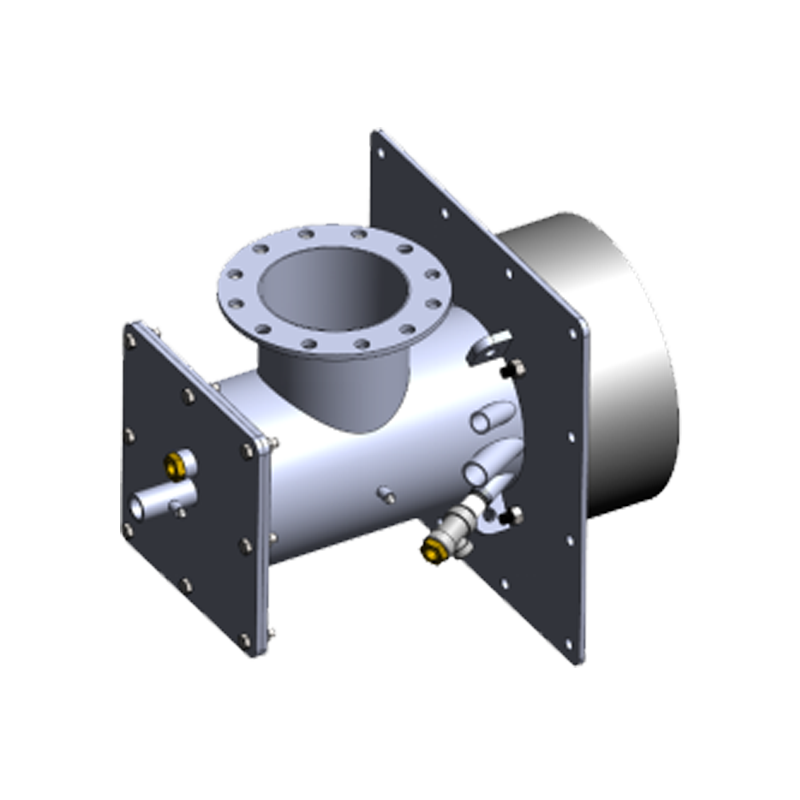

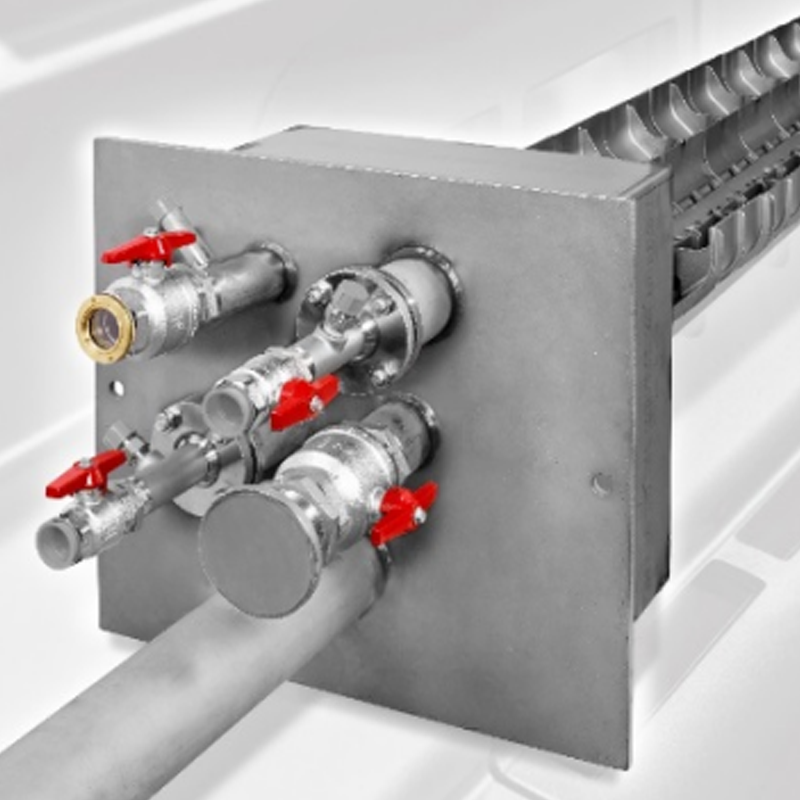

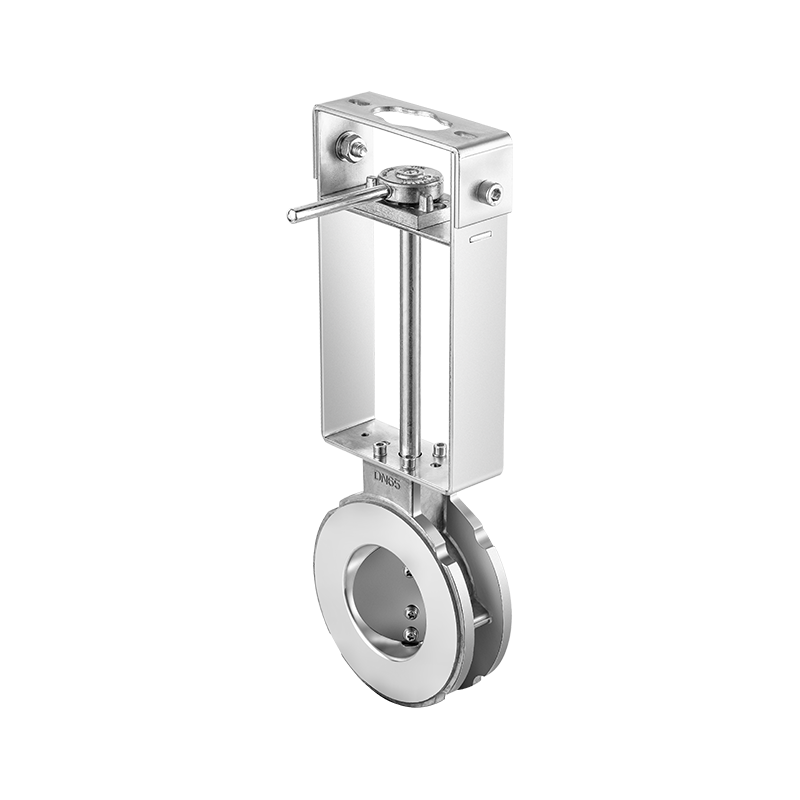

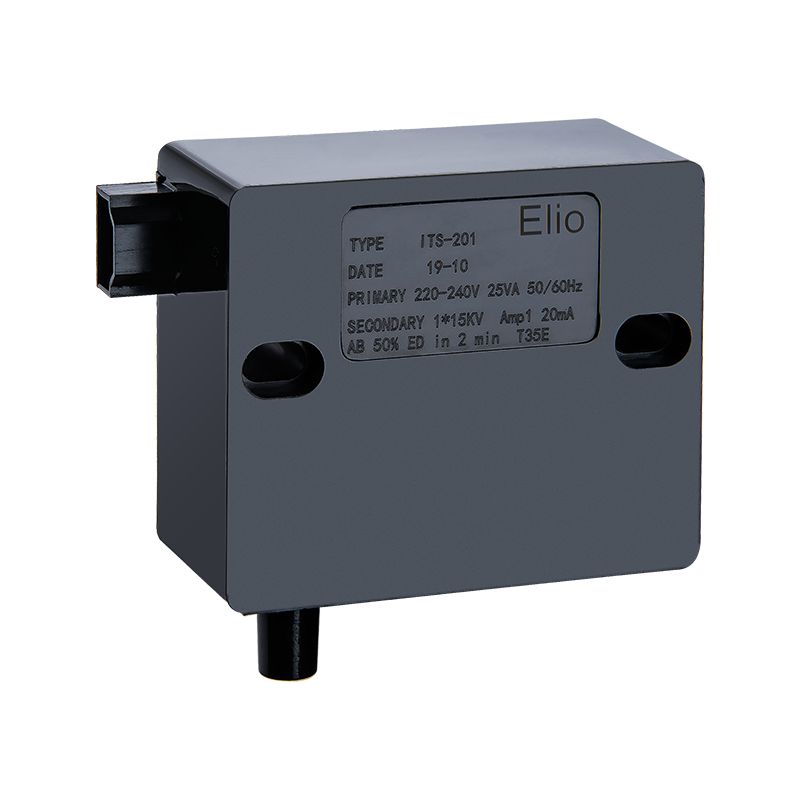

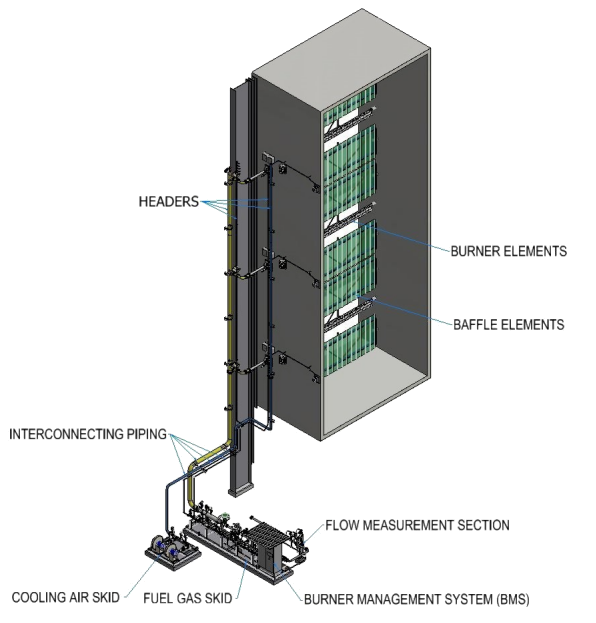

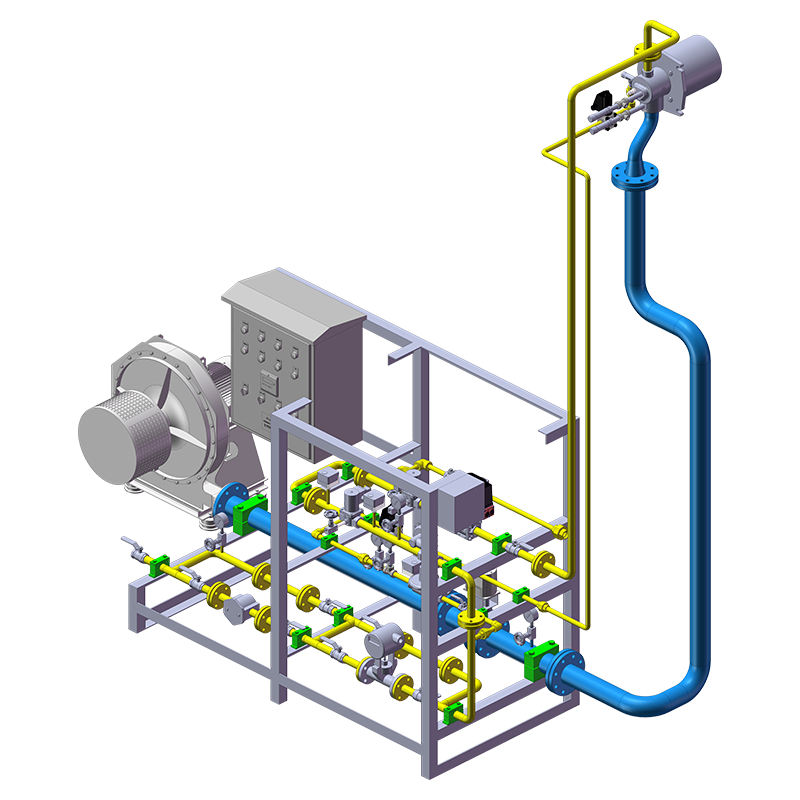

Grid duct burner system layout

Installations

English

English 中文简体

中文简体 русский

русский

.jpg)